- 60W Solar Panel

- 100W Solar Panel

- 200W Solar Panel

- 450W Solar Panel

- 550W Solar Panel

- 200W Power Station

- 300W Power Station

- 500W Power Station

- 700W Power Station

In Lipower, we have set up high quality standards and established strict inspection procedures. All of our products are 100% tested to ensure their superior quality, stable performance during long lifespan. Following this rigorous quality system, we guarantee that the defective rate of our products is lower than 2‰, and each unqualified product is recorded and analysed by joint efforts from our QA team and R&D team, aiming to get better quality.

Basic Function Tests

Circuit Protection Function Tests

Extreme Temperature Tests

Drop & Vibration Tests

100% Aging Tests

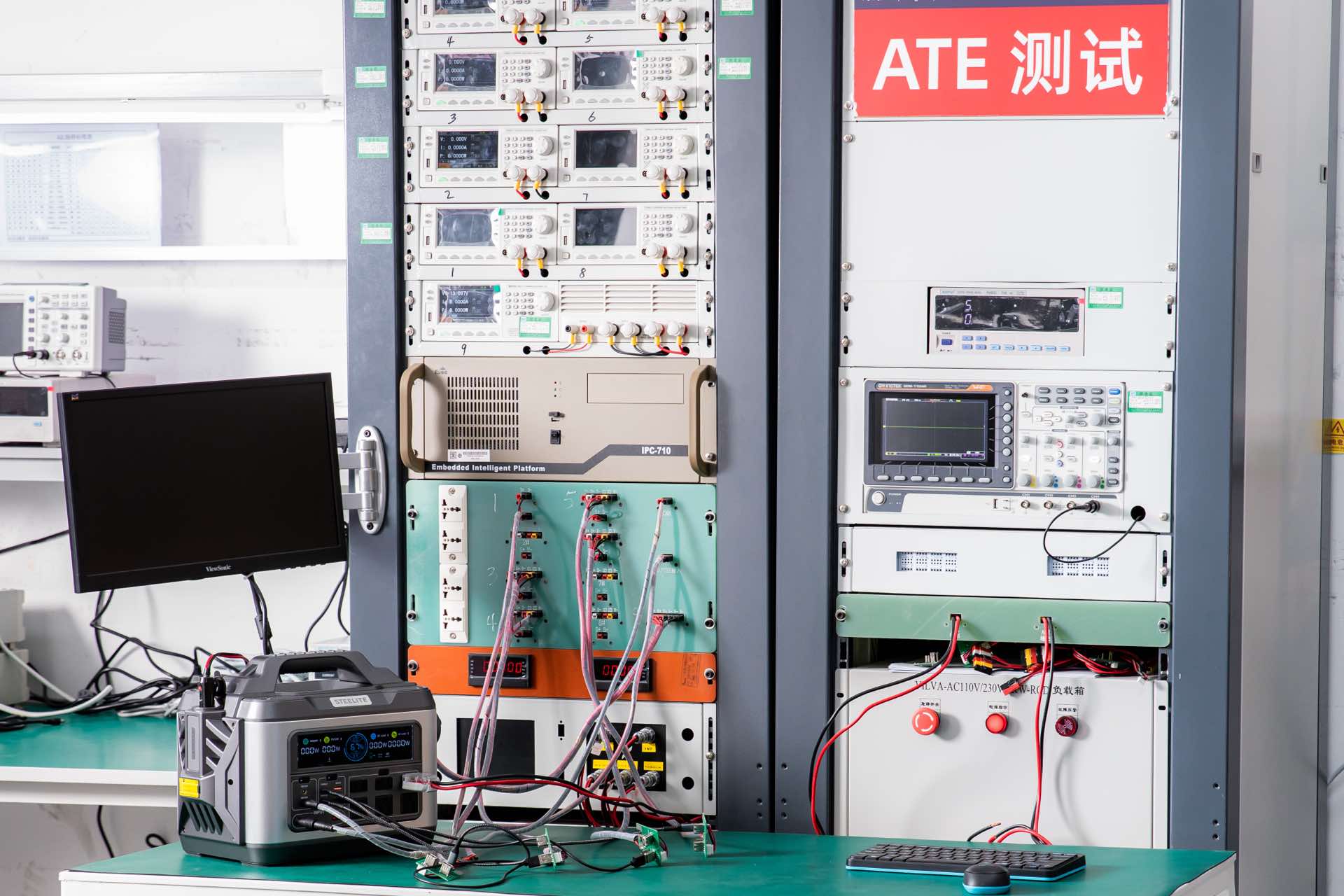

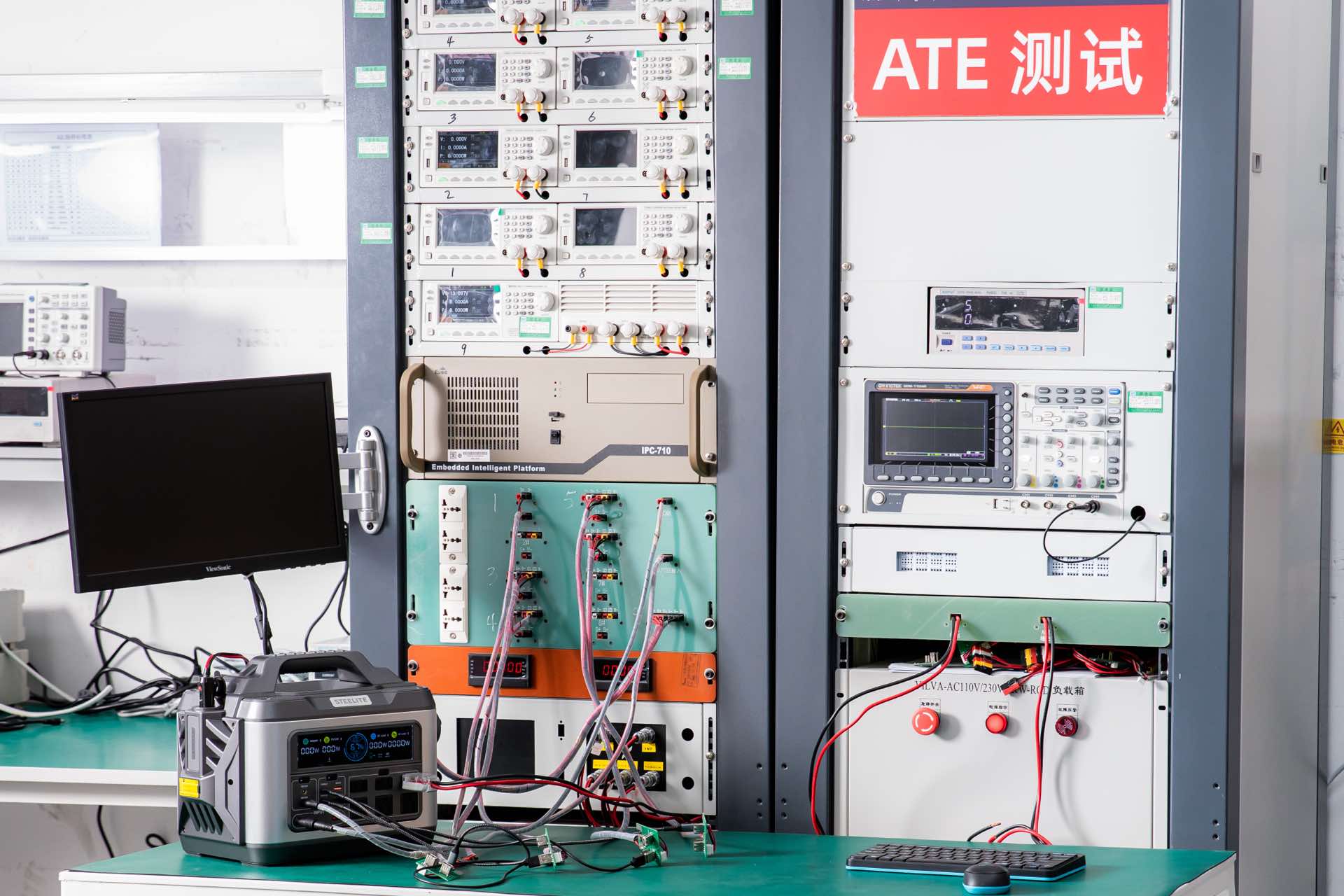

Basic function test is conducted to check all the outputs, including AC, DC, USB, TYPE, can function properly. This inspection is done with the assistance of the fully-automatic ATE machines, which is more accurate in statistics compared with manual inspection.

In this test, we connect the product to automatic ATE inspection machine to make sure the circuit protection can function properly under the occasions when the product is overloaded, overcharged, over-discharged or in short circuit and other potential safety hazards.

The portable power station is tested under the highest temperature of 80℃ and the lowest temperature of -65℃ for at least 2 hours to see if it can maintain stable performance under these extreme working conditions.

This test includes dropping the portable power station from 1 m above the ground and putting it on the vibration shelf to test if it can withstand the fall and still work.

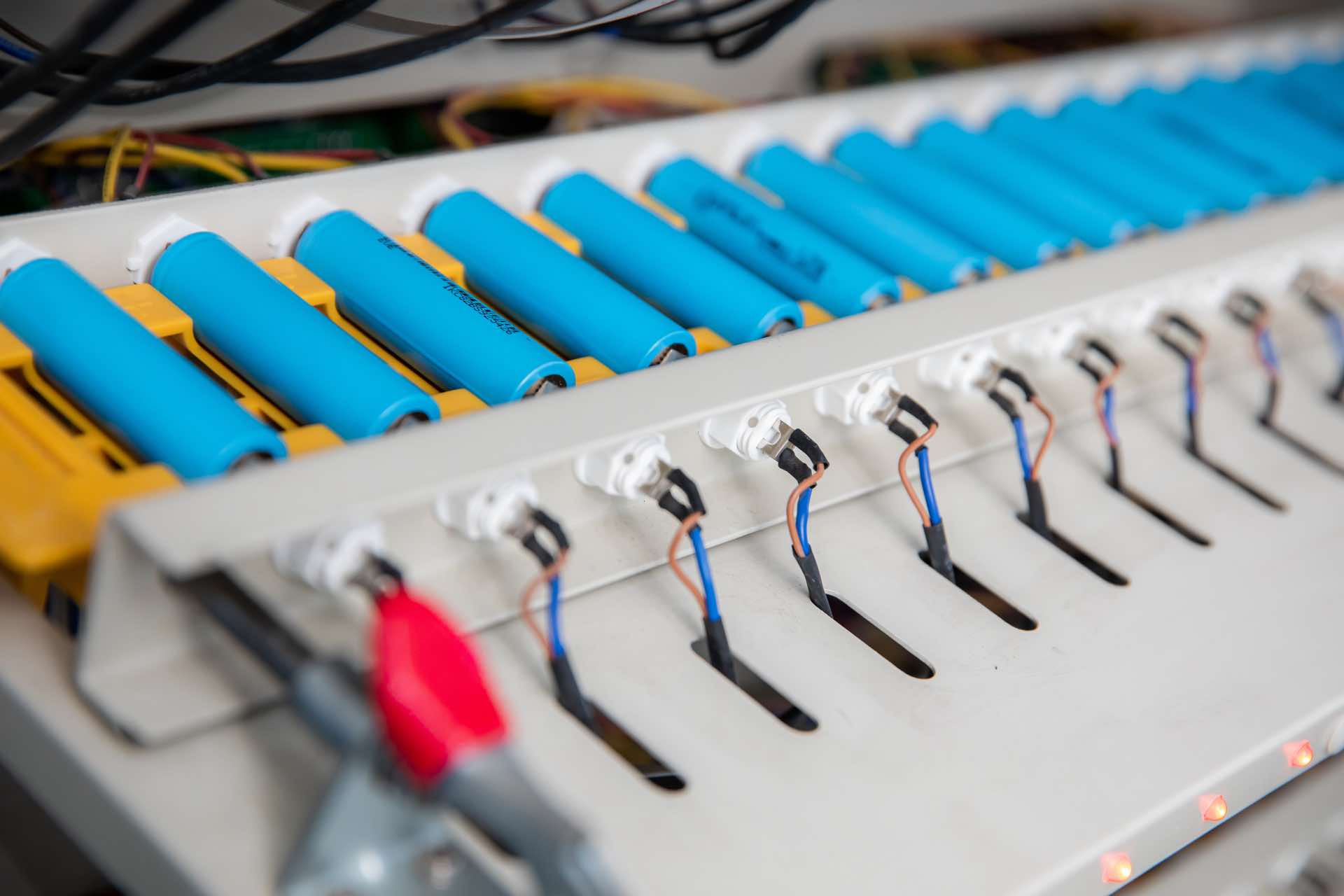

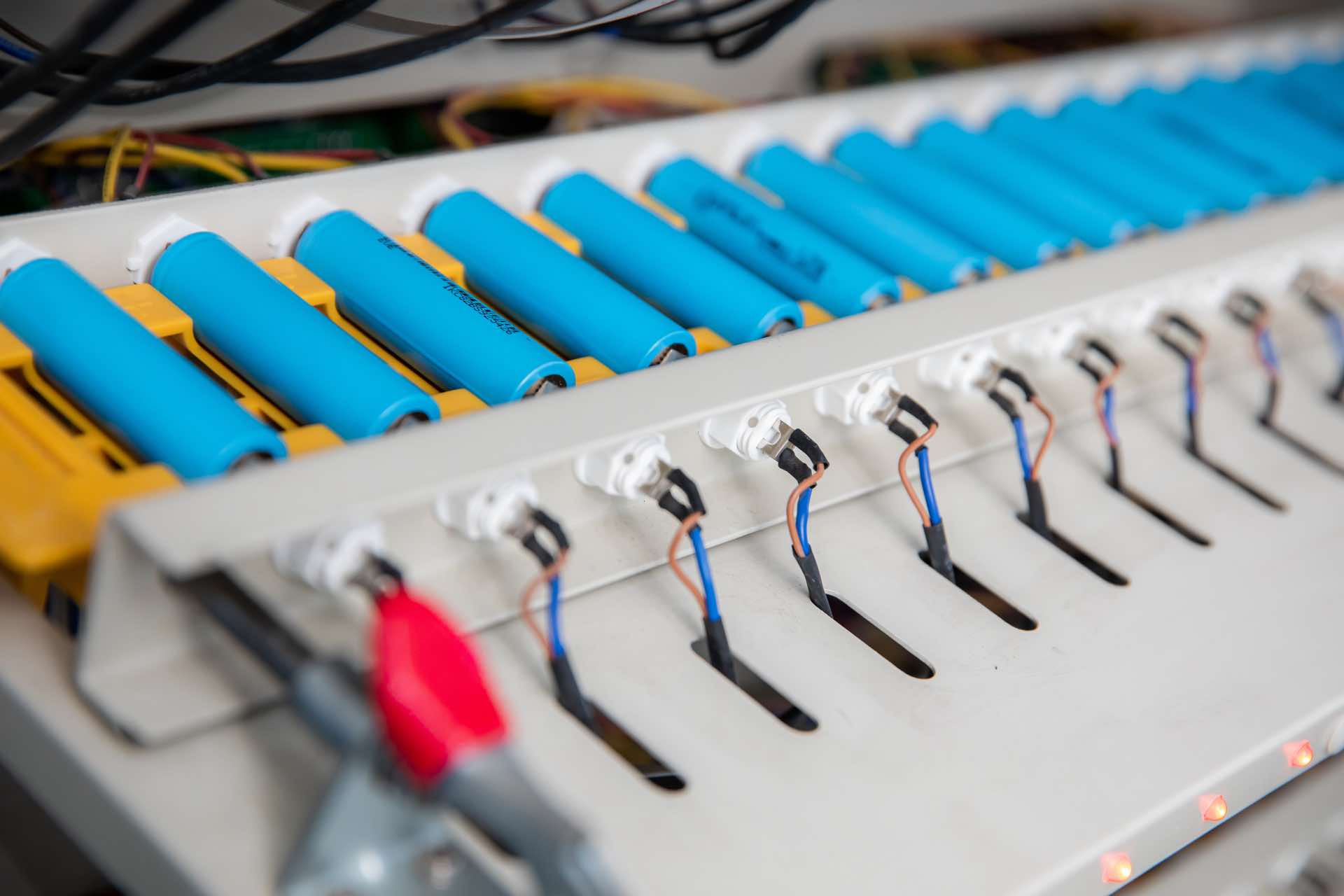

To ensure a long-lasting lifespan, all the battery packs and finished portable power stations are fully charged and completely discharged for 2 cycles. During this period, any abnormal conditions will be recorded and inspected later.

We have more than 10 experienced members in our QA team, the average working experience of whom is over 10 years.

Besides, we have quality inspection engineers who used to work for a battery industry giant.

Thanks to their great efforts, Lipower earns its reputation for quality.

Lipower owns professional QA labs. The capacity of our aging test lab ranks among the top 3 in the industry, which

in turn is a very critical factor in determining our productivity.

*We respect your confidentiality and all information are protected.